CREATING UNIQUE INDUSTRIAL EQUIPMENT

FROM IDEA TO BUILDING IN METAL AND FULL LIFE CYCLE SUPPORT

ABOUT THE COMPANY

01

02

Production

Engineering

We perform machining and assembly of unique products at our own production facilities. We have established relationships with reliable contractors in the industry

03

Equipment supply

We develop engineering documentation based on your idea. We make conceptual design and full set of working drawings. We build equipment of any complexity

We supply ready-made vacuum equipment from our partner in China. Competitive prices and a wide range available in stock

04

Comprehensive problem solving

From defining the technical task to launching the finished product into operation

01

WE CREATE TURNKEY EQUIPMENT FOR VARIOUS TASKS

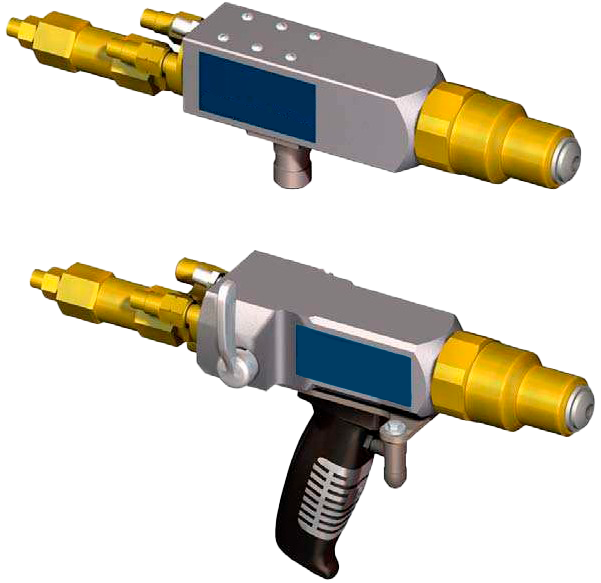

Gas, plasma, ultrasonic spraying.

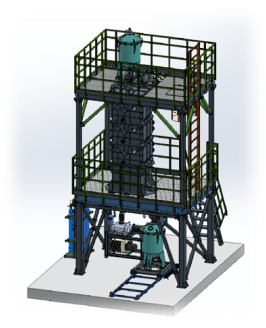

Installations for granule separation

Installations for granule separation

Powder metallurgy

Pumps, valves — we select and supply according to the customer's needs

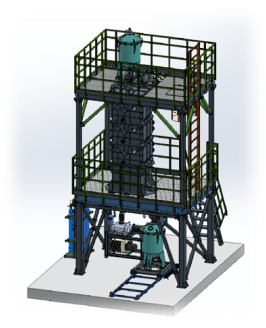

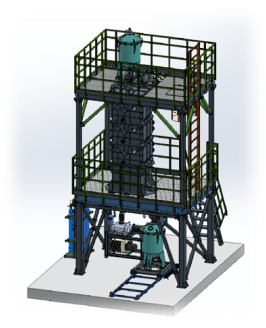

Turnkey vacuum furnaces, thermoblocks —designed and manufactured according to drawings, complete cycle

Vacuum thermal and casting equipment

Equipment for creating vacuum

Diffusion, cvd, pvd, plasmatrons and complex installations — proprietary developments designed to meet customer needs

Coating application

With over 10 years of experience and 50+ completed projects

We prepare and coordinate the technical specifications ourselves, develop drawings and project documentation.

We carry out the entire production cycle until commissioning

Experienced team

Provides supplies of a wide range of finished equipment from China at the best prices

DVE China Partner

For manufacturing and servicing products of any complexity

In-house production capacities

04

02

03

01

We take on projects from the idea stage

WORK PROCESS

WORK PROCESS

Area approximately

Administrative premises around

Inventory of mechanical equipment around

Leningrad Oblast, Pavlovo settlement

2000 sq. m.

500 sq. m.

45 units of machines

Own repair-mechanical and assembly workshops

Skilled staff

PRODUCTION CAPABILITIES

Area

Tver Oblast, Rzhev city

Inventory of mechanical equipment

2000 sq. m.

Own assembly workshop

around 150 units of machines

Skilled staff

TECHNOLOGICAL COMPETENCIES

Powder metallurgy

Gas spraying

Plasma spraying

Coating application

Ultrasonic spraying

Vacuum casting equipment

VACUUM THERMAL FURNACES

Designing, manufacturing according to drawings, full cycle

Plasma

Diffusion

CVD

PVD

Designing, manufacturing according to drawings, full cycle

VACUUM THERMAL FURNACES

Spheres:

Application:

Aerospace industry

Electronics

Semiconductor manufacturing

Scientific research

Electronics

Semiconductor manufacturing

Scientific research

Thermal processing of materials under vacuum or inert atmosphere conditions. Vacuum environment is necessary to prevent oxidation and contamination of processed materials, as well as to obtain more uniform and controlled heating;

Enable processes such as annealing, quenching, tempering, aging, sintering, and others;

Vacuum casting equipment

Spheres:

Application:

Aerospace industry

Automotive manufacturing

Medicine

Energy industry

Jewelry industry

Automotive manufacturing

Medicine

Energy industry

Jewelry industry

Creating high-precision and high-quality parts: vacuum casting allows control over the metal pouring process, ensuring high precision and quality of the obtained parts;

Reducing impurities and defects in casting: during metal casting, exposure to air can lead to the formation of oxides and other defects. The use of vacuum casting equipment helps reduce the occurrence of such defects as the process takes place in a low-pressure air environment;

Enhancing mechanical properties of parts: due to the controlled casting process and the absence of atmospheric air influence, parts obtained through vacuum casting exhibit superior mechanical properties compared to those produced by traditional casting methods;

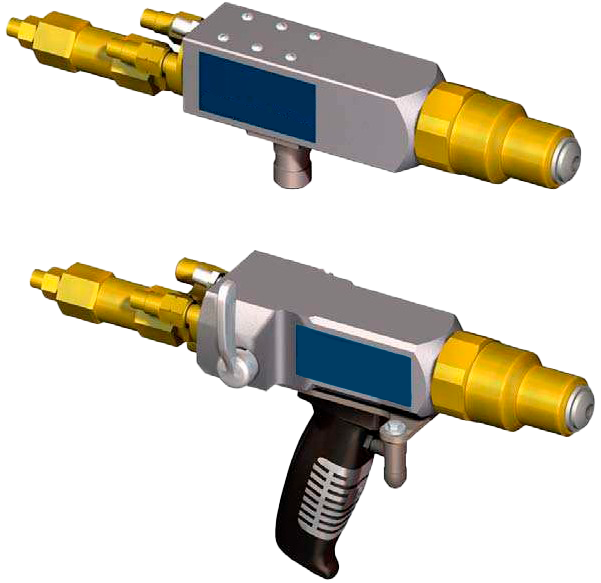

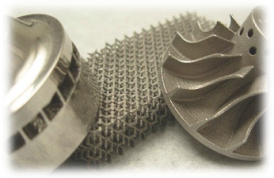

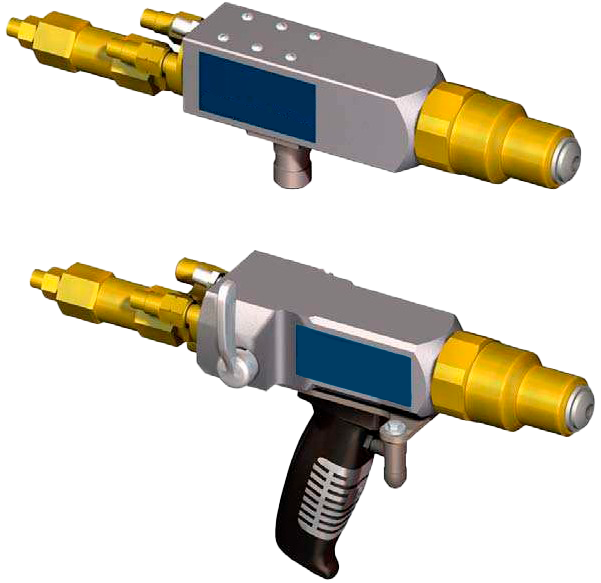

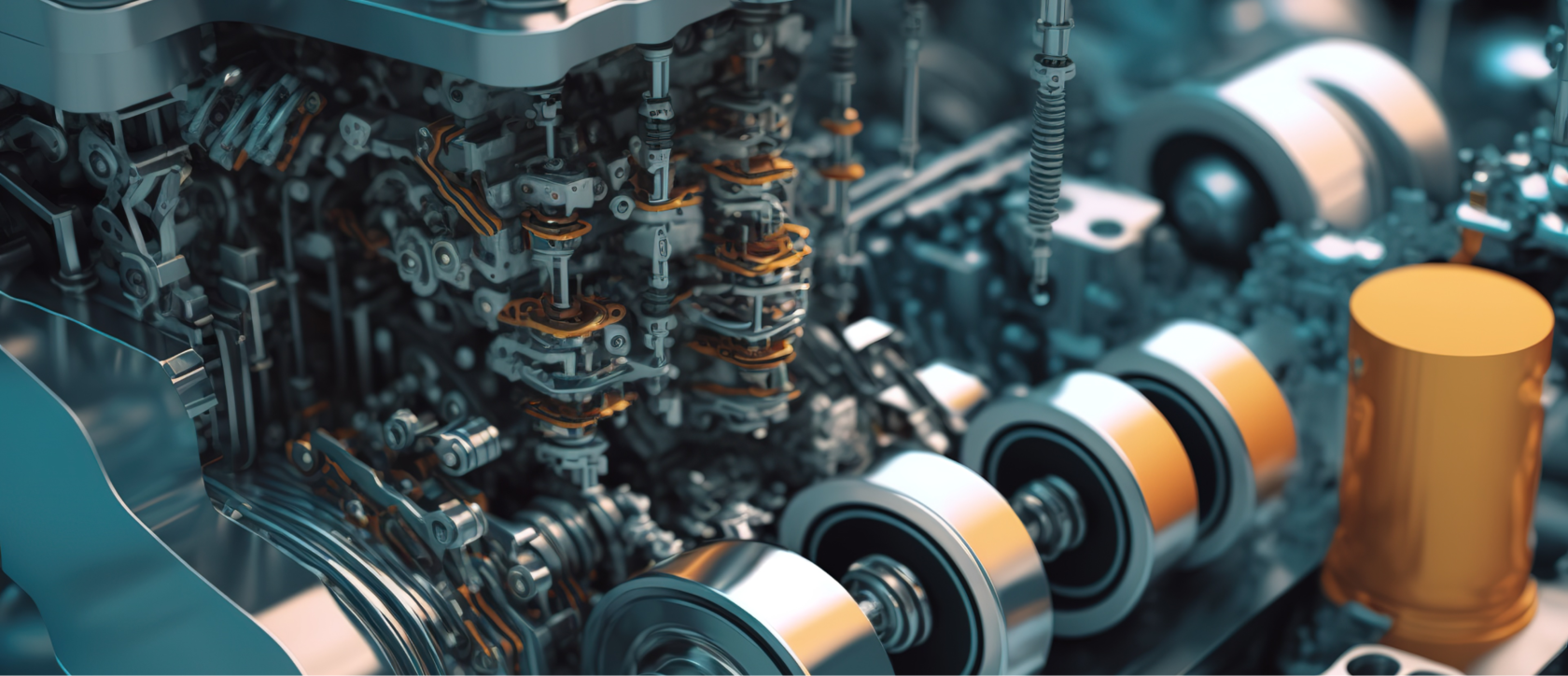

Coating application

Spheres:

Plasma

Diffusion

Application:

CVD

PVD

Aerospace industry

Engine building

Engine building

Protecting surfaces from various types of impact: wear, corrosion, oxidation, high temperatures, and more

Creating durable and lightweight coatings on various parts of aircraft, such as turbine blades and airplane wings

Establishing thermal insulation coatings on surfaces of spacecraft, satellites, and other space vehicles

Applying coatings on engine and turbine components to increase their wear resistance and extend their lifespan

Producing parts and components from complex alloys and ceramic materials

We have prototypes of plasmatrons of our own design with a capacity starting from 25 kW

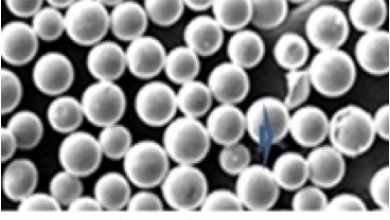

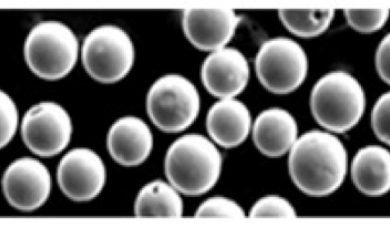

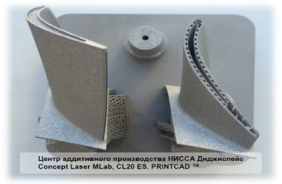

Powder metallurgy

Spheres:

Gas spraying

Plasma spraying

Ultrasonic spraying

Aerospace industry

Manufacturing of automotive parts

Tooling industry

Manufacturing of electronic components

Manufacturing of automotive parts

Tooling industry

Manufacturing of electronic components

Application:

Production of complex-shaped items that are difficult or impossible to produce using traditional casting or molding methods;

Production of complex-shaped items that are difficult or impossible to produce using traditional casting or molding methods;

Creation of materials with unique properties unattainable through other means. For instance, it’s possible to create a material with high strength and corrosion resistance or with low density and high thermal conductivity

The technological process for manufacturing products from powders

Powders

PROJECTS IMPLEMENTED BY THE ZMZ TEAM

Назад

OUR PARTNER

About partner:

- The company was founded in 2000

- Specializes in the manufacturing and design of various vacuum pumps and vacuum systems

DEVELOPMENT VACUUM

EQUIPMENT CO.,LTD.

EQUIPMENT CO.,LTD.

Contacts:

Donggang Industrial Park, Xiling, Sanmen, Zhejiang, China

ENTERPRISES FROM VARIOUS INDUSTRIES COOPERATE WITH US

Aerospace

Turbomachinery

Metallurgy

04

Engine manufacturing

02

03

01

Office:

172 332, Russia, Tver region, Zubtsov city 25 Parizhskoy Kommuny Street, office 2

+7 (901) 123-50-05

Main production site:

8 (800) 550-94-93

187 323, Russia, Leningrad region, Pavlovo

Leningradsky Prospekt, 7

Leningradsky Prospekt, 7

CONTACTS

You may contact us via any means of your choice, or fill in the form